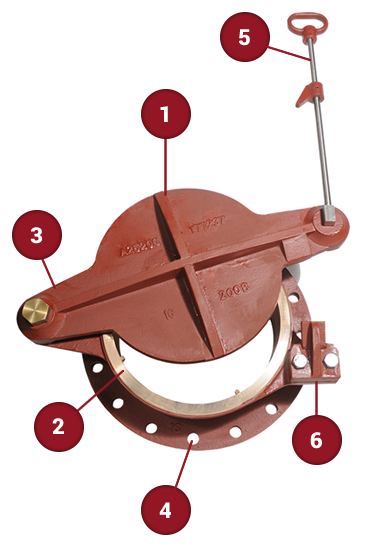

Shear Gate Valves

Mind If We Cut In?

Shear gates are designed for use in lines of low seating pressure for filling and emptying tanks, low sludge discharge lines and similar applications. Shear gate valves are ideal for tanks where sludge tends to stick. They provide a tight shearing action upon closing that removes any sludge remaining on the seat of the valve.

Standard Features

As opposed to fabricated parts, our cast parts have less potential for failure over time.

Our machined seat provides a strong surface for shearing.

Our flap valves have a coating that gives lasting protection against corrosion.

To allow for easy use of the lift rod, we’ve offset the bolt circle of the body flange 30 degrees from the center line.

A 2 foot lift rod is provided in steel with a cast iron handle and hook catch, but the rod is available in stainless steel at a variety of custom lengths.

Our unique single wedge design allows for complete closure, while double wedge gates can cause the disc to get hung up on the wedge on the pivot side and not allow the disc to engage the wedge on the handle side.

Operation

The valve is operated by manually lifting the pull rod connected to the disc. The valve may be held in various open positions by using the adjustable catch hooks on the pull rod.

Maintenance

Body and disc are shop coated at the manufacturing facility. Periodic visual inspection of the coating is recommended with field cleaning and painting as required. The seating may be adjusted by tightening or loosening the hinge bolt nut to change the relationship between the hinge bolt and wedge. Use a feeler gauge of .004 to adjust gate disc to the proper seat gap around the total seating circumference.

Installation

Valve shall be mounted using a standard 125-lb. flange. The valve is mounted at a 30-degree offset from the vertical center line to allow for proper closure.

Parts

Parts are available by request. Please contact us for more information.

You Have A Problem. We Have The Solution.

Confidence