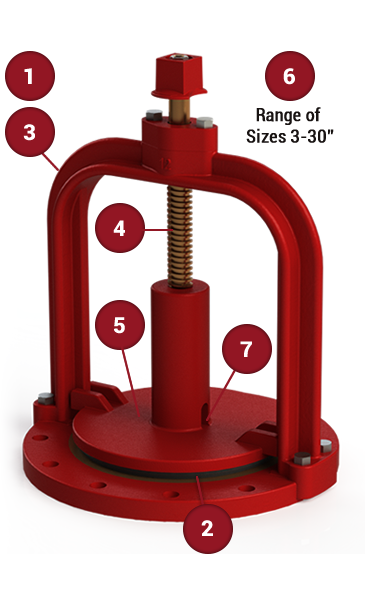

Premium Cast Iron Epoxy Coated Mud Valve for Reliable Performance

The Ultimate Mud Valve Solution

The Troy Valve Cast Iron Epoxy Coated Mud Valve is a robust and reliable solution for effective water management in potable and wastewater systems. Engineered for durability and ease of use, this valve is an essential component for efficient fluid control.

Why Troy Cast Iron Mud Valves?

Compatible with a 2" square nut, sleeve coupling, hand wheel, and floor stand, offering flexible operation options. Ideal for diverse settings, from sludge environments to clean water systems.

Patented design forms a bubble-tight seal that won’t leak, even when minor debris obstructs the valve.

Superior mud cast protection with an epoxy coating that meets NSF-61 standards, ensuring long-term performance.

Extra strong, low torque stem exceeds AWWA specs.

No holes mean fewer opportunities for leaks.

From 3" - 30", we have a mud valve that can meet your specifications.

This critical feature allows sludge to drain out so your valve won't jam.

Typical Configurations

Find all the operator options there are for your mud valve application.

Download Configurations PDF

Mud Valve Operators

Find all the operator options and accessories you need for opening and closing your mud valve.

Featured White Papers

Seal Upgrades

+ Viton®

+ EPDM

Operation and Maintenance

Installation

- Standard Mount: Install the valve on a standard 125-lb. ANSI flange.

- Flush Drainage: Recess the valve so the flange sits flush with the floor for complete drainage. Ensure the mounting surface is flat and debris-free.

- Prevent Damage: Protect the machined bronze seat during installation, especially from heavy grit like concrete. Use a blind flange as a placeholder during concrete pouring.

Operation

- Versatile Control: This mud valve offers flexible operation using a 2" square nut, handwheel, or floor stand (connected via an extension stem).

- To Open: Turn the operating mechanism counterclockwise.

- To Close: Turn the operating mechanism clockwise.

Maintenance

- Durable Coating: The yoke, plug, and frame are protected with an NSF-approved epoxy coating, suitable for both drinking water and wastewater systems.

- Easy Lubrication: The valve comes pre-lubricated with food-grade grease. Relubricate the stem and lifting nut with a similar grease during routine tank maintenance.

Need Parts?

Parts are available by request. Please contact us for more information.

You Have A Problem. We Have The Solution.

Confidence